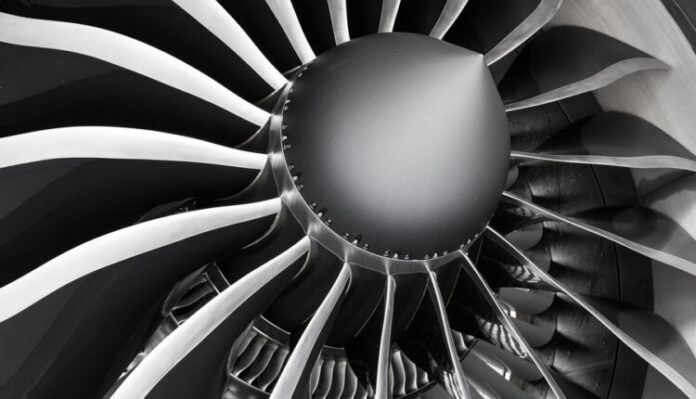

CAMBRIDGE, MA: Titanium alloys have long been prized for their exceptional mechanical properties, corrosion resistance, and lightweight characteristics, making them essential structural materials in various industries, including aerospace, energy infrastructure, and biomedical equipment. Traditionally, improving the strength of these alloys has often come at the expense of ductility, and vice versa. However, researchers at MIT, in collaboration with ATI Specialty Materials, have discovered a novel approach to create titanium alloys that break this historical tradeoff, leading to new applications.

The groundbreaking findings are detailed in the journal Advanced Materials, authored by Shaolou Wei ScD ’22, Professor C. Cem Tasan, postdoc Kyung-Shik Kim, and John Foltz from ATI Inc. The team’s innovative approach involves meticulously tailoring the chemical composition and lattice structure of the alloy, coupled with optimized industrial-scale processing techniques.

Titanium Alloys: The Big Playground

Titanium alloys have maintained their importance due to their superior properties compared to traditional steels. By carefully selecting alloying elements and their proportions, and optimizing the processing methods, researchers can create various structures that offer desirable property combinations for both cryogenic and elevated temperatures.

“This diversity in structure creates a big playground to achieve good property combinations,” says Professor Tasan. However, the plethora of possibilities requires a method to guide selections to meet specific application needs. The analysis and experimental results presented in this study provide such a framework.

Multi-Scale Structural Considerations

The properties of titanium alloys are governed by their structure at the atomic level. Some titanium alloys feature two intermixed phases, known as the alpha and beta phases. The researchers’ key strategy involves design considerations at multiple scales:

- Crystal Scale: By carefully choosing alloying elements, the researchers achieved a more ideal crystal structure of the alpha phase, enabling specific deformation mechanisms.

- Polycrystal Scale: This involves interactions between the alpha and beta phases. The design approach considers both scales, ensuring optimal performance.

Role of Processing Techniques

Beyond selecting the right materials and proportions, processing techniques play a crucial role. The team discovered that a technique called cross-rolling was instrumental in achieving the exceptional combination of strength and ductility.

Experimental Insights and Findings

Collaborating with ATI researchers, the team tested various alloys under a scanning electron microscope during deformation, observing how their microstructures responded to mechanical loads. They identified a specific set of parameters — including composition, proportions, and processing methods — that produced a structure where the alpha and beta phases deformed uniformly. This uniform deformation mitigates the tendency for cracking between the phases, resulting in a superior material.

“We looked at the structure of the material to understand these two phases and their morphologies, and we looked at their chemistries by carrying out local chemical analysis at the atomic scale. We adopted a wide variety of techniques to quantify various properties of the material across multiple length scales,” Tasan explains. The outcome: properties significantly better than comparable alloys.

Commercial and Industrial Implications

This research, supported by ATI Specialty Rolled Products, aims to prove design principles for alloys that can be commercially produced at scale. Professor Tasan emphasizes, “What we do in this collaboration is really toward a fundamental understanding of crystal plasticity. We show that this design strategy is validated, and we show scientifically how it works, leaving room for further improvement.”

Potential Applications

The new titanium alloys hold great promise for any aerospace application where an improved combination of strength and ductility is beneficial. This invention opens up new opportunities for the aerospace industry and beyond.

The work utilized facilities at MIT.nano and the Center for Nanoscale Systems at Harvard University, showcasing a successful collaboration between academia and industry aimed at pushing the boundaries of materials science.